VISION blast chillerstechnological excellence

Thanks to the continuous dialogue with top Chefs and Pastry Chefs, Coldline has developed the VISION F and VISION NUVŌ™ blast chillers which offers every professional the most suitable appliance for their business.

Powerful, reliable and eco-friendly

These are the main features of the new Vision blast chillers. A new evolutionary step that further raises the standards for one of the fundamental products in kitchens and pastry laboratories.

R290 gas, natural and ecological power

Vision's wide range of blast chillers is equipped with R290 natural gas, a solution that cancels out environmental impact and enables energy-efficient cooking.

ACOUSTICCOMFORT

New low-noise refrigeration systems ensure greater acoustic comfort

SINGLE-PHASE 10 AND 14 TRAYS BLAST CHILLERS

The 10 and 14 trays models with single-phase power supply simplify installation operations

SIMPLIFIEDMAINTENANCE

Pressure transducers allow you to check the quantity of refrigerant gas directly from the touch screen

NUVŌ™

Cooking & Cooling

NUVŌ™ is the revolutionary patented technology that allows food to be cooked at low temperatures with the use of steam, and which also combines the blast chilling and freezing cycles.

When using NUVŌ™, food is completely enveloped by hot steam. The micro particles of water ensure excellent heat transmission which results in homogeneous and delicate cooking.

With NUVŌ™, the entire Cook & Chill process takes place without the need to move trays or trolleys, or the need for manual intervention. Once cooking is complete, chilling, freezing and conserving at the desired temperature can be programmed.

Control

at your fingertips

Customised recipe book

You have customisable programs for each food type.

Personal layout

You can change the position of the recipe keys and create your own layout.

Chained programs

Hot and cold functions can be performed in automatic sequence.

Manual cycle

Work at the temperature you want by selecting optimal ventilation intensity and humidity percentage.

Scheduled notifications

An alarm warns you when the set time or temperature has elapsed.

Display lock

You can lock the display to prevent tampering by unauthorised personnel.

Controls

TemperaturE

Select the perfect temperature to work and store your preparations

Humidity

Set the humidifier between 45% and 95% to define the humidity percentage

Ventilation

Set the ideal ventilation intensity between 25% and 100%

TIME

Work with core probe programs or leave it to Devote™

VISION blast chillers functions. Freedom to work from -40° to +85°C with steam.

BLAST CHILLING

Quickly cools fresh or cooked food to a core temperature of +3°CVISION F | NUVŌ™

BLAST FREEZING

Quickly cools fresh or cooked food to a core temperature of -18°CVISION F | NUVŌ™

MANUAL CYCLE

Keeps food at desired temperatureVISION F | NUVŌ™

THAWING

Safely and quickly thaws food while maintaining the original qualityVISION F | NUVŌ™

Proving and retarder proving

Creates the ideal micro-climate by adding moisture for perfect provingVISION F | NUVŌ™

Chocolate crystallisation

Pralines, chocolates and chocolate bars crystallise in a few minutesVISION F | NUVŌ™

HOLDING

Maintain ice cream, desserts, cakes and dishes at a temperature ready to serveVISION F | NUVŌ™

Desiccation

Gently dehydrates food and extends storage timesVISION F | NUVŌ™

Yoghurt

Allows you to make creamy natural yoghurt using only good-quality milk.VISION F | NUVŌ™

Pasteurisation

Eliminates pathogenic micro-organisms in foods and extends storage timesVISION NUVŌ™

Low temperature steam cooking

Gently cooks food at a controlled temperature while adding moistureVISION NUVŌ™

Steam sanitisation

The blast chiller compartment is steam sanitised, thus removing odours and food residuesVISION F | NUVŌ™

VISION,

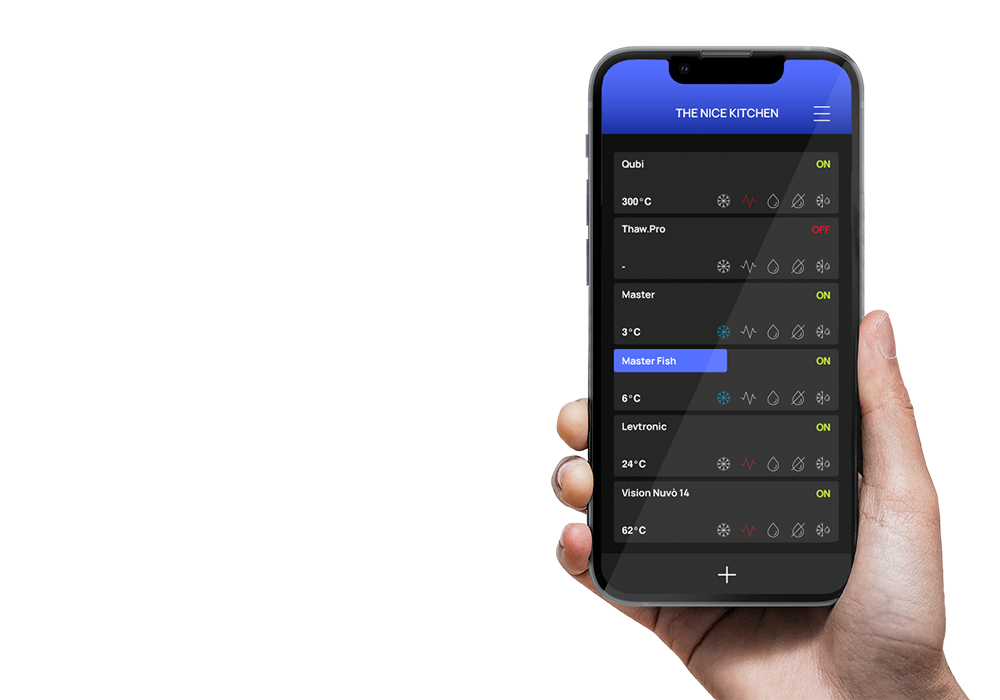

an hub in the Cosmo

Cosmo is the innovative Wi-Fi technology that allows you to connect all the Coldline

appliances in the kitchen to VISION and monitor them from your smartphone. Wherever you are, control is always in your hands.

Blast chill and freeze

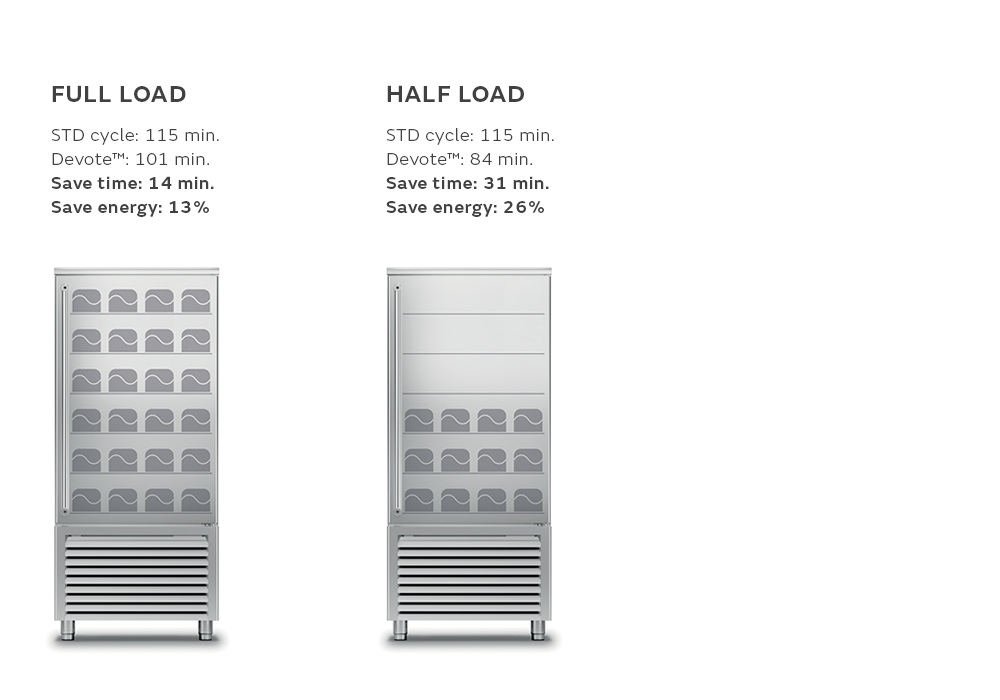

without a probe:

Devote™ takes care of it

Devote™ - Dynamic Evolution Temperature - is the innovative system developed by Coldline which is able to autonomously recognise the weight, size and initial temperature of the food.

Devote™ automatically modulates temperature and ventilation on blast chilling and blast freezing cycles in the shortest time possible without using a core probe.

Limiting the use of the core probe allows you to speed up the chill blasting and freezing processes, thus avoiding bacterial contamination between different foods.